Ruth Díez-Ahedo MBA, PhD works since 2012 in TEKNIKER in the surface chemistry and nanotechnology department working in the area of surface chemistry, sensors and project management. She also coordinates the agrifood sector in Tekniker.

Xabier Bazan is Mechanical Engineer (2005) and Industrial Automation and Electronics Engineer (2006) by the University of Navarra. In 2007 he joined Tekniker and since 2017 he has been working in the Electronics and Communications Unit where he has been developing his activity in the fields of IoT technologies, wireless connectivity, embedded firmware development and work with sensor systems. His role in the project will be to carry out preliminary testing of the dust sensors, prepare their technical and installation documentation, and provide the necessary technical support for the deployment of the dust sensors by the demo sites.

One of the most underestimated performance killers in photovoltaic (PV) plants is soiling. Soiling refers to the accumulation of dust, dirt, sand, pollen, bird droppings, industrial pollution, or other particulates on the surface of solar modules.

Cleaning PV panels is essential for maintaining their efficiency and energy output since soiling can accumulate on solar panels, obstructing sunlight and reducing their ability to generate electricity. Soiling not only reduces the amount of sunlight reaching the photovoltaic cells, which directly affects energy production, it leads accelerated degradation that affects the plant’s lifetime. Dirt and its uneven accumulation on the panels creates shading patterns that force some cells to work harder, heating them up and shortening the module’s lifespan. Moreover, soiling accelerates wear on anti-reflective coatings and glass surfaces.

PV plants, particularly in dusty or arid regions, may require frequent cleaning, which means high labour, use of water, and logistics expenses increasing O&M costs.

Optimized cleaning programs, instead of cleaning the panels according to a fixed schedule, result in higher performance and greater profitability.

Optimized cleaning periods

SOILING SENSORS are becoming increasingly important in modern photovoltaic (PV) plants, especially as plants scale up to hundreds of MW and operate in harsher climates. By knowing exactly when soiling losses start to impact output, cleaning operators can intervene at the right time.

Soiling sensors are underused because they suffer from the lack of correlation models between the sensor signals, actual soiling and power output. Moreover, market available dust sensors are large and integrated in the PV systems, which means that their calibration needs to be done onsite in not ideal light condition, which can imply some deviations and inaccuracies. All these features often make the sensor expensive and not easy to integrate on the field.

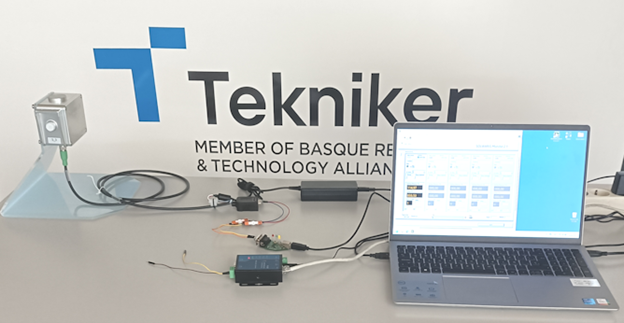

|

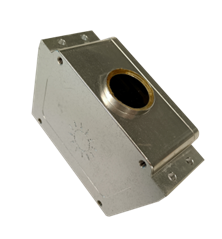

Figure 1. Solaris soiling sensor ready to plug¬play installation under real scenario. |

SOLARIS SOILING SENSORS (Figure 1) rely on the projection of a controlled infrared light beam under the dust that accumulates on a transparent substrate and the measurement of the scattered light from those particles. This sensor offers the advantages of i) operating at accurate signal levels under broad environmental conditions, ii) autonomous independent operation, iii) more compact design and lower estimated cost, while maintaining the most relevant characteristics, such as the absence of moving parts, and the fact that it does not require sunlight to operate. SOLARIS SOILING SENSORS will help PV operators balance cost vs. yield, reduce uncertainty, and make plants more efficient and sustainable avoiding unnecessary water-intensive cleaning.

Water based fluids for delayed soiling

Apart from soiling sensing, whose final aims is to define a tailored cleaning schedule, other strategies can be adopted to facilitate and/or delay the cleaning of the panels.

Traditional cleaning methods, such as manually wiping or using water hoses, require labour, equipment, and water resources. Self-cleaning panels reduce the need for frequent maintenance and cleaning, making them more cost-effective over their lifespan. Less frequent cleaning also means fewer abrasions and damages caused by harsh cleaning methods. By reducing the need for chemical cleaners or excessive water use, self-cleaning solar panels are more eco-friendly.

Most treatments are based on functional thin films that provide the desired optical and self-cleaning properties. These treatments are normally applied during the panel manufacturing process because they require high temperature curing process. Moreover, they can also content micro/nanostructures that enable super- hydrophobic/hydrophilic effects that are vulnerable to environmental wear (e.g., wind erosion, temperature fluctuations), leading to performance degradation over time.

To reduce environmental impact and improve durability of the self-cleaning properties, new water-based anti-soiling cleaning fluids will be development during SOLARIS project. The aim is to develop a water-based cleaning fluid to minimize the cleaning frequency by preventing or delaying the build-up of soil and thus, maintaining the panel’s energy conversion over time.

These cleaning fluids are obtained by adding specially designed additives directly to the cleaning water. These additives delay soiling by reducing the adhesion of particles to the surface, making it easier for rain or wind to naturally remove the contaminants. The new cleaning fluids will provide a protective barrier, making future cleaning easier and more effective without modifying the glass of the PV panel and avoiding contaminant substances as fluorinated products or surfactants. Soiling is typically addressed through self-cleaning properties associated by either highly hydrophobic or hydrophilic surfaces.

(Super)hydrophobic surfaces allow efficient removal of dirt facilitated by droplets sliding over the surface carrying the dust and contaminants and preventing adhesion. These cleaning fluids when applied to surfaces aims to create a protective layer that reduces surface adhesion of dust and dirt. Moreover, when it rains, water forms beads that roll off the surface dragging the dirt with them.

On the contrary, (super)hydrophilic surfaces allows water spreads into a thin water film, rather than forming droplets. This film helps wash away dust, dirt, and organic contaminants during rainfall or cleaning. The coating reduces adhesion forces between dirt particles and the surface, making them easier to remove.

Water-based cleaning fluids are being developed by sol-gel reaction under a variety of conditions. Sol-gel precursors will be hydrolysed in the cleaning water itself, so that when applied to the glass, they will be covalently anchored, producing semipermanent effect that is longer lasting than current cleaning solution. The cleaning fluid will be applied using standard cleaning procedures used in PV plants.

Conclusion

Soiling sensors, together with water-based cleaning fluids, are promising solutions to keep solar panels surfaces clean for longer time and to reduce the frequency of cleaning procedures, minimizing the use of water, and O&M costs.